Home » News about Abbey Extrusions » Low-Density Polythene (LDPE) Tubing, What Is It & What Can It Be Used For?

Medium & Low-Density Polythene (LDPE) Tubing, What Is it & What Can It Be Used For?

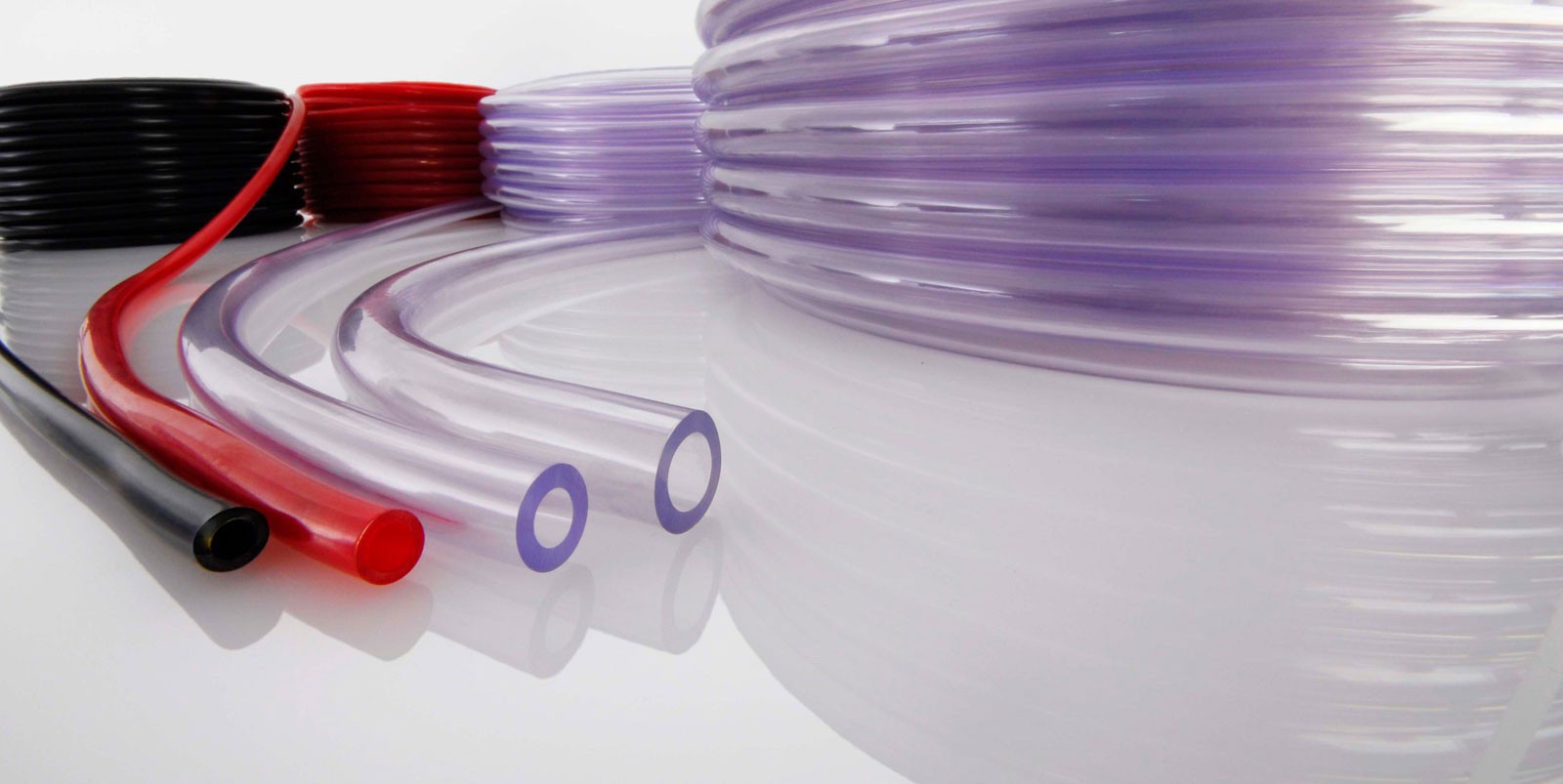

Low-Density Polythene (LDPE) Tubing is a flexible, high-quality form of Polyethylene Tube made from Low Density Polyethylene. As a result, it is well renowned for its chemical resistance and good resistance to moisture; and has become the best solution for low-pressure applications across a wide range of sectors.

Consequently, in everyday life, you will see it in food packaging, irrigation systems, and even in the conveyance of beer and soft drinks within the Beverage Industry as well.

In this guide, we will explore the unique properties, key features, and industrial applications of LDPE tubing. For example, we will discuss how its excellent resistance to various chemicals, low temperatures, and everyday wear makes it a staple in the automotive industry, domestic services, and medical fields.

By the end, you will then have a clearer picture of why LDPE Low tubing might be the best solution to support your specific needs, and if you are still not sure, our team is on hand to help you.

What is Low-Density Polythene (LDPE)?

Low-Density Polythene (LDPE) is a type of polyethylene plastic produced by polymerising ethylene under high pressure. This process leads to a lower density than High-Density Polyethylene (HDPE), creating a more branched structure. As a result, LDPE is softer, more flexible, and easier to mould than many other types of tubing.

Some Key Differences from Other Polyethylenes

Linear Low-Density Polyethylene (LLDPE Tubing)

LLDPE has a more linear structure, which gives it greater tensile strength and tear resistance while remaining flexible.

High-Density Polyethylene (HDPE)

HDPE has fewer branches, making it more rigid and suitable for higher temperatures and load-bearing applications.

Because of these variations, Low-Density Polythene (LDPE) tubes are often chosen for flexible tubing and plastic wraps, where a low-cost yet effective solution is needed under room temperature and low-pressure conditions.

Designed for High-Demand Applications

Our LDPE tubes excel in durability, chemical resistance, and quality assurance. They can handle daily wear as well as industrial needs. Whether you need them for irrigation systems, food packaging, or conveying beverages, their excellent temperature resistance makes them reliable for both high and low temperatures.

High Purity & Food Quality

Because LDPE is non-toxic, it is frequently used in food packaging and applications requiring high purity. You will often find LDPE tubing in soft drink dispensers, domestic services, and commercial beverage setups, helping to maintain the quality of the product being transported.

Understanding LDPE’s Chemical Composition

The benefits of LDPE largely come from its chemical make-up and the way it is produced.

Polymerisation & Branched Structure

Low-Density Polythene (LDPE) is made through a high-pressure polymerisation process, which creates a branched molecular structure. This branching prevents molecules from packing closely, leading to softness, flexibility, and good chemical resistance.

Temperature Range

LDPE generally operates well from below freezing up to around 60°C for continuous use.

Melting Point

LDPE melts around 105°C – 115°C, making it easy to shape through extrusion and moulding.

How Are LDPE Tubes Manufactured?

Raw Materials

Ethylene, sourced from natural gas or petroleum, is polymerised to create LDPE resin.

Extrusion

The resin is fed into an extruder, melted, and pushed through a die to form the tubing. This process dictates wall thickness, outside diameter, and inner diameter.

Quality Control

We perform quality checks at each stage—monitoring temperature, pressure, and consistency—to ensure uniform properties and high-quality LDPE tubing.

The result is a broad range of LDPE tubes that handle various working pressure levels. They are especially suitable for low- or medium-pressure setups requiring flexible tubing.

Why Choose LDPE Tubes & What Are Their Key Features & Benefits?

LDPE tubing offers a blend of affordability, flexibility, and chemical resistance, making it ideal for numerous applications. Key features include:

Excellent Chemical Resistance

LDPE resists a wide range of acids, alkalis, and solvents.

Flexible and Durable

Its branched structure allows bending without cracking, even at low temperatures.

Lightweight and Easy to Handle

With a density of about 0.91–0.94 g/cm³, it’s simple to install.

Cost-Effective

Provides a budget-friendly yet sturdy option for many industries.

Wide Temperature Range

Remains supple in cold climates and tolerates moderate high temperatures.

Food Safe

Perfect for food and beverage uses, including soft drink dispensers and beer lines.

Main Application Uses

LDPE tubes fit various industrial tasks, from irrigation systems to the automotive sector.

Common Application Uses

Pharmaceutical & Medical

Ideal for drug delivery, IV lines, and lab equipment thanks to high purity.

Food & Beverage Industry

Transfers liquids like soft drinks or water without contamination.

Agricultural Irrigation Systems

Resists weathering and chemicals used in farming, making it perfect for drip lines.

Automotive Industry

Used for windshield washer tubing and fluid transfer due to its chemical resistance.

Laboratory & Chemical Transfer

Withstands a wide range of chemicals for safe handling.

Industrial Fluid Handling

Reliable for solvents, mild acids, and more.

Protective Coverings & Wiring

Offers insulation and protection for cables.

Domestic Services

Common in plumbing lines and flexible hoses for household appliances.

Chemical Compatibility

Below is an example of how LDPE stands up to various chemicals:

| Chemical | Resistance | Typical Use |

|---|---|---|

| Acetic Acid | Excellent | Transport/storage of acetic acid solutions |

| Sodium Hydroxide | Excellent | Caustic solutions and alkali transfer |

| Hydrochloric Acid | Good | Low-concentration HCl solutions |

| Sulfuric Acid | Fair | Dilute acid applications |

| Ethyl Alcohol | Excellent | Alcohol transport/storage |

| Benzene | Poor | Not recommended |

| Toluene | Poor | Not recommended |

For most low-pressure applications, LDPE provides superb resistance to everyday chemicals, while retaining its tensile strength and integrity.

Flexibility & Strength of this Type of Tubing

LDPE’s branched molecular structure lends it considerable flexibility. This feature helps it withstand repeated bending with a lower risk of kinking. Despite its softness, it offers decent tensile strength, resisting tears or ruptures during use. This balance of toughness and flexibility makes LDPE a strong choice for sensitive applications such as food packaging and medical uses.

Frequently Asked Questions

Is LDPE tubing safe for food contact?

Yes. LDPE does not release harmful chemicals and is commonly approved for food packaging and beverage lines.

Can LDPE tubing handle outdoor conditions?

It offers good UV resistance and a wide temperature range, making it suitable for both indoor and outdoor setups, including irrigation.

What if I need sturdier tubing?

If you need a more rigid option, consider High-Density Polyethylene (HDPE) or LLDPE tubing for higher working pressure and firmer properties.

Can I get a custom size?

Absolutely. We can customise wall thickness, outside diameter, and inner diameter to meet your specific requirements.

Bespoke Tube Solutions

If standard sizes are not sufficient, we offer customised solutions to match unique project needs. Whether you require Black LDPE for enhanced UV protection, a particular flow rate, or specific dimensions, we can design the perfect fit—often at a competitive price. We’re available Monday to Friday, dedicated to delivering the right product on time.

Get a Quote Today

Interested in exploring LDPE tubing further, or wondering if a Linear Low-Density Polyethylene or High-Density alternative might suit your applications better? Our experts can help you find the best solution for your precise requirements—be it LDPE, LLDPE, or another plastic tubing type.

We also offer:

– Next Day Delivery options

– Assistance with specialised working pressure or unique property requirements

– Quality Assurance from start to finish

Contact us now to learn more about our wide range of Low-Density Polythene tubes. Whether you’re handling domestic services, automotive tasks, or simply need the perfect tubing for the beverage industry, we’re here to guide you to the most dependable LDPE solution.

Bespoke

Can't find the right tube to meet your unique requirements?

We have decades of experience in creating custom tube solutions for a wide range of industries, ranging from the pharmaceutical industry to the aeronautics sector.