Home » News about Abbey Extrusions » What is Polyurethane and why are our Polyurethane Tubes suitable in Pneumatic Control Systems?

What is Polyurethane and why are our Polyurethane Tubes suitable in Pneumatic Control Systems?

What is Polyurethane?

Polyurethane is a very flexible elastomer – a synthetic polymer with elastic properties. The main advantage of Polyurethane is that it has:

Anti Bacterial Properties

Polyurethane does not support mould, mildew, fungus or other similar growth.

Abrasion & Impact Resistance

This property is ideal in helping to prevent our tubing from being damaged and causing the inner contents to leak and flow outside of the tubing due to exterior damage.

Electrical Properties

Polyurethane has an excellent electrical insulating property.

Flexibility

Our polyurethane air tubing performs well for flexible applications with a tight bend radius. This unique tubing feature assists with maximum kink resistance and minimum kink memory, making it an excellent choice for use in confined spaces. This feature helps prevent damage to the tubing, allowing easy movement of the tube installation.

High Load Bearing Capacity

Polyurethane has a high compression load capacity. It may change shape under a heavy load but will return to its original form once removed.

Resistance to Gases, Fuels, Oils, and Water

Polyurethane will remain stable in or carrying: Gases, Fuels, Oils, and Water.

REACH, RoHS and ISO compliant

Our Polyurethane tubing is REACH, RoHS and ISO compliant, which addresses the production and use of chemical substances and their impacts on health and the environment.

Tear Resistance

Polyurethane possesses high tear resistance along with high tensile properties.

What is Pneumatic Control Systems Used For?

Pneumatic systems and devices use pressurised air or gasses, which power equipment with compressed air or inert gases. Part of their makeup is the tubing which will carry compressed gas such as air, compressed air, or inert gases. This feature is where our polyurethane tubing comes in.

Why are our Polyurethane Tubes suitable in Pneumatic Control Systems?

This form of pneumatic tube is suitable mainly because of all their amazing properties above. They are tough, flexible and have a high load-bearing capacity, so they don’t damage easily. Alongside this, they are flexible, which can make moving them around a lot easier, along with them being placed within tight compartments.

Working pressures

The working pressures of our polyurethane tubes are based on the short-term burst pressure at a temperature of 20°C using a 4:1 safety factor.

The maximum recommended continuous working temperature is 55°C with occasional short-term use at 85°C. Minimum temperature use is occasional use at -55°C.

Our standard coil lengths are 30 metres; however, if you are looking for alternative coil lengths, we provide customised solutions, so our sales team will be happy to discuss your options.

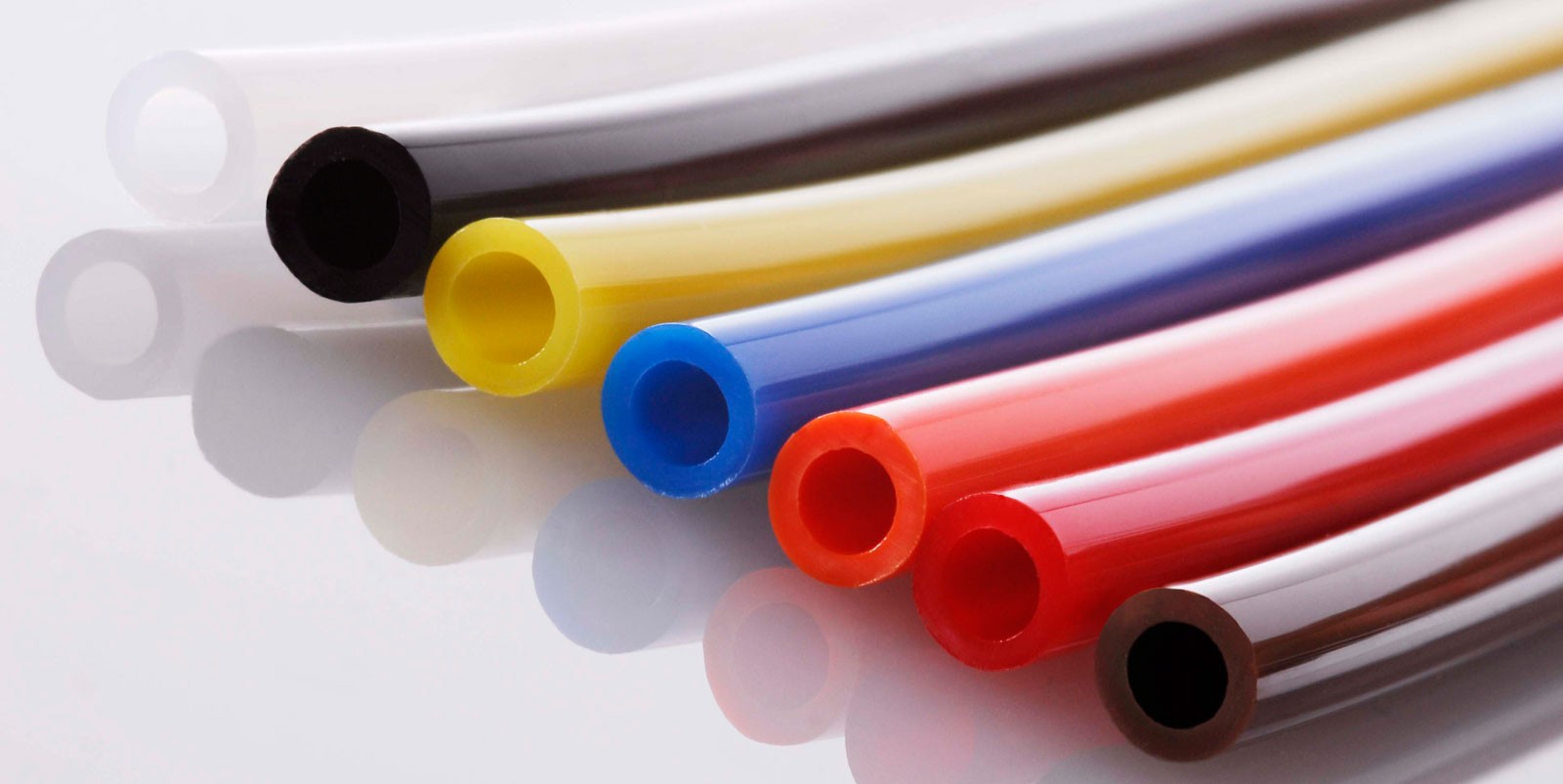

All tube sizes are also available in various colours and tints.

What is Polyurethane?

Polyurethane is a versatile polymer composed of organic units joined by carbamate (urethane) links. It is widely used in many applications due to its flexibility, durability, and resistance to abrasion and solvents.

What are the Advantages of Using Polyurethane Tubes?

Polyurethane tubes are known for their excellent flexibility, high abrasion resistance, superior tensile strength, good chemical resistance, and a wide range of hardness. They are often used in applications where rubber or plastic tubes might fail.

Are Polyurethane Tubes Resistant to Chemicals?

Yes, polyurethane tubes resist oils, solvents, fats, greases, and gasoline. However, their chemical resistance can vary based on the type of polyurethane and the specific chemicals involved.

Can Polyurethane Tubes Be Used for Food and Beverage Applications?

Specific grades of polyurethane tubes are suitable for food and beverage applications. Ensuring that the tube is certified for food-grade use and complies with relevant safety standards is essential.

What Temperatures Can Polyurethane Tubes Withstand?

Polyurethane tubes typically operate effectively in various temperatures, but their specific temperature tolerance can vary. Generally, they can handle temperatures from around -40 °C to 80°C, but specialized grades may extend this range.

How Do Polyurethane Tubes Compare to Rubber Tubes?

Polyurethane tubes often outperform rubber tubes regarding abrasion resistance, flexibility, and durability. They are also more resistant to oils and solvents but may be less flexible at lower temperatures compared to some rubber materials.

Can Polyurethane Tubes be Recycled?

Recycling of polyurethane materials can be challenging due to their chemical structure. However, there are methods like regrinding or chemical recycling, but the feasibility depends on the local recycling facilities and policies.

What Sizes and Shapes Are Available for Polyurethane Tubes?

Polyurethane tubes come in various sizes and diameters and can be custom-made to specific dimensions. They are usually round, but some manufacturers may offer other profiles depending on the application.

How to Store Polyurethane Tubes Properly?

Store them in a cool, dry place away from direct sunlight, extreme temperatures, and moisture. They should also be kept away from sharp objects and surfaces that might cause abrasion.

What Applications Are Polyurethane Tubes Commonly Used For?

They are widely used in pneumatic and hydraulic lines, fuel and oil transfer, material handling, robotics, medical devices, and in industries such as automotive, aerospace, and manufacturing.

Remember, the specific properties and suitability of polyurethane tubes can vary depending on the manufacturer and the type of polyurethane used. Always check with the supplier for the most relevant information for your specific application.

Not sure if this is the right product for you?

If you are still trying to figure out if this is the right product for your needs, please feel free to contact us for more information. Do call us for a friendly chat with our expert sales team.

Bespoke

Can't find the right tube to meet your unique requirements?

We have decades of experience in creating custom tube solutions for a wide range of industries, ranging from the pharmaceutical industry to the aeronautics sector.