Flexible Nylon Tube & Hose UK Manufacturer

Flexible, lightweight and durable over a wide temperature range, our nylon tube is the go-to tube choice for several purposes, such as pneumatic control systems, fuel lines, and food and beverage production lines.

or call us to discuss your requirements on:

01530 416177

Nylon Tubing Details

Get the best experience with this viscosity extrusion-grade flexible hose, which is strong and durable and will perform well against a wide range of chemicals. Consequently, we manufacture our premium Nylon Tubing, especially to meet the highest industry standards, which makes this tubing ideal for a wide range of applications—from fluid transfer to pneumatic systems to applications requiring push-in fittings.

What is Nylon Tubing?

Nylon tube is a semi-flexible tube, that is regarded highly for its exceptional stability, mechanical strength, and resistance to chemical corrosion; it is considered one of the most versatile engineering materials, with so many application uses to its name.

This versatility is why we use nylon PA612 (grilamid2D25w20x natural polymer to manufacture this tube. It is also heat and light-stabilised to precise tolerances, creating a flexible, lightweight, durable line which has improved flow capabilities as a result.

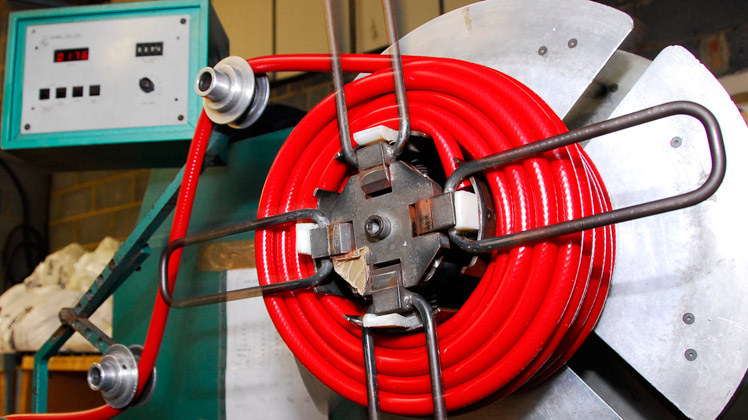

We can also manufacture semi-rigid nylon tube in the same sizes as our standard nylon tube for higher temperatures and pressures, and our tubing is supplied on hose reels in varying metre rolls.

Nylon Tube Key Features

This flexible tube has the following benefits:

- Flexible over a wide temperature range

- Tough, Lightweight and durable

- Flexible for routing into tight spaces

- Chemical, moisture and abrasion resistant

- Corrosion resistant

- Low water resistance and lower water absorption

- Low moisture absorption

- Withstand repeated flexing

- High resistance to vibration

- REACH, RoHS and BSI ISO 9001 compliant

- Improved flow capabilities

Application Examples

This flexible tube is also suitable for use with or alongside:

- Air systems

- Air compressors

- Airlines

- Airline Filters

- Airline Lubricators

- As Cylinder Accessories

- Ball Valves

- Brass Solenoid Valves

- Butterfly Valves

- Gate Valves

- Flojet G57 Pumps

- Pressure Gauges

- Inflation Stations

- Jubilee Hoses

- Hosetail Adaptors

- Hose Clips and Tube Connectors

- Mindman MCGS Cylinder

- Industrial Applications

- ISO Cylinders

- Varying Valve Types

- Regulator Lubricators

- Pneumatics & Hydraulics Equipment

- Stainless Steel Tools

- Sub Base Valves

- Standard Guided Cylinders SMC MGPM

- Spray equipment

- Tyre Inflation and Tyre Inflator Equipment

- Worm Drive Pumps

We can also manufacture dedicated air hoses if this is something you are also interested in.

BS 5409 Compatible

This hose is also compatible with applications requiring to meet BS 5409 standards as well.

Nylon Tube Material

Manufactured from high-grade Nylon that is FDA-compliant and meets UL standards.

Nylon Tube Durability

Exceptionally resistant to abrasion, crushing, and cracking, ensuring a long service life.

Nylon Tube Flexibility

With a seamless construction, the tubing offers exceptional flexibility for easy installation and routing.

Nylon Tube Temperature Range

Performs excellently in a wide temperature range, from -40°F to 200°F (-40°C to 93°C).

Nylon Tube Chemical Resistance

It is highly resistant to oils, greases, and many solvents, making it perfect for chemical transfer applications.

Nylon Tube Colour Options

Available in natural, black, and custom colours for easy system identification.

Nylon Tube Sizes

Offered in various sizes, lengths, and wall thicknesses to meet your specific requirements.

Nylon Tube UV Resistance

Integrated UV stabilisers make this tubing ideal for outdoor use.

Semi-rigid option is available

Further to this, Nylon Tubing has several features. These include:

High temperature resistance

Our nylon tubing can maintain integrity with occasional use at up to 120°C and 140°C, making it suitable for many high-heat applications.

Low temperature resistance

To complement its high-temperature resistance, Nylon tubing can also be used in environments of -40°C – again making it suitable for many applications.

Nylon Tube High pressure resistance

If you are looking for excellent pressure resistance, our nylon tubing suits you; however, we can manufacture this in flexible and semi-rigid materials, depending on your bespoke needs. Please refer to our WP/BP charts.

High resistance to abrasion

This tubing has high abrasion resistance, making it ideal for applications that carry liquids or gases. This abrasion resistance will help to prevent accidental damage to the tubing that will cause leakages or spillages.

Nylon tubing is highly suitable in automotive systems due to its exceptional abrasion resistance. This quality makes it ideal for applications where the tubing is exposed to friction and wear, providing reliable performance and durability.

Nylon 12 Polymer

Our nylon tubing comprises Nylon 12, a polymer renowned for its excellent properties. Nylon 12 exhibits remarkable characteristics, including exceptional resistance to abrasion, heat, cold, and other factors, ensuring reliable performance in various applications.

What is Nylon Tubing made from?

Nylon tubing is a type of thermoplastic polymer tubing with several benefits and uses in various industries. It is known for its flexibility, strength, and durability, making it an ideal choice for multiple applications.

How is Nylon Tubing made?

The manufacturing process produces the tubing material by extruding nylon resin through a die to form the tube shape. After forming the tube, it cools down before being cut to the desired length. This method ensures the precise creation of nylon tubing for various applications.

High strength, abrasion resistant durable

One of the key benefits of nylon tubing is its strength. Nylon is a highly durable material that can withstand high pressure, making it an excellent choice for high-pressure applications.

The strength of our nylon tubing is of utmost importance in applications that subject the tubing to high-stress levels. These applications include hydraulic systems, fuel lines, and pneumatic systems, where the tubing must withstand and perform reliably under demanding conditions.

Flexibility

Another vital benefit of nylon tubing is its flexibility. Unlike rigid metal or plastic piping, nylon tubing can bend and conform to the shape of its surroundings, making it an ideal choice for applications where flexibility is required.

Our nylon tubing’s flexibility significantly contributes to applications requiring the tubing to route through tight spaces or around corners. This flexibility enables easier installation and manoeuvrability, ensuring the tubing’s efficient routing in various challenging environments.

Anti vibration properties

Additionally, nylon tubing can absorb vibrations, reducing the stress on connected components. It is ideal for applications where vibration is a concern.

High chemical resistance

Nylon tubing is also known for its resistance to various chemicals. Our nylon tubing is well-suited for applications that involve exposure to harsh chemicals. Its chemical resistance properties make it an ideal choice for environments where the tubing needs to withstand contact with various corrosive substances and maintain its integrity and performance over time. Nylon is highly resistant to multiple chemicals, including fuels, oils, and solvents. It is ideal for use in automotive systems and fuel lines.

UV resistance

Besides its other beneficial qualities, Nylon also resists UV light, which makes it highly suitable for outdoor applications. This UV resistance ensures that the nylon tubing maintains its structural integrity and performance even when exposed to prolonged sunlight, making it a reliable choice for various outdoor applications.

Application uses

Nylon tubing is used extensively across a wide range of industries and applications. Its versatility and excellent properties make it a popular choice in automotive, aerospace, manufacturing, chemical processing, medical, and many others. It serves diverse applications such as fluid transfer, pneumatic systems, fuel and oil lines, hydraulic systems, robotics, instrumentation, and more. The broad applicability of nylon tubing highlights its significance in numerous industrial sectors.

Nylon tubing is vital in various automotive industry applications. It is commonly used in fuel lines, ensuring efficient and safe fuel transfer within the vehicle. Additionally, it finds application in transmission cooler lines, helping to cool and regulate the temperature of the transmission fluid. Nylon tubing is also employed in vacuum systems, contributing to the proper functioning of various components.

Furthermore, it can be utilised in engine management systems, where it aids in delivering fluids and gases to support engine operations.

Manufacturers like us employ nylon tubing to construct hydraulic, fuel lines, and pneumatic systems in the aerospace industry.

The medical industry utilises nylon tubing in surgical instruments, catheter tubing, and dialysis machines.

Nylon tubing is also commonly used for beverage dispensing systems and food processing equipment in the food and beverage industry.

Highly customisable tubing

Nylon tubing is highly customisable, and it has various applications. Manufacturers can cut it to specific lengths, mould it into custom shapes, and join it to other pieces of tubing using fittings and connectors.

This customisation allows the creation of unique systems that meet specific requirements, making it ideal for applications where a standard product may not be suitable.

What sizes ; colours can Nylon Tubes come in?

Our nylon tubing is available in a range of sizes.

Sizes

The standard coil length is 30 metres, although alternative coil lengths are available.

Colours

This tubing is available in:

- Nylon Tube Natural

- Black Nylon Tube

- Red Nylon Tube

- Blue Nylon Tube

- Green Nylon Tube

- Yellow Nylon Tube

- Orange Nylon Tube

- Brown Nylon Tube

- Grey Nylon Tube

- Pink Nylon Tube

If you have any questions, contact our sales team. They are always happy to discuss how we can help with client requirements.

What is Nylon Tube used for?

Particularly popular within the pneumatics industry, our nylon tube is suitable for many additional purposes, such as pneumatic control systems, fuel lines, lubrication lines, food and beverage uses, brewing and production lines.

The brewing, beverage, and pneumatics industries are the primary sectors that utilise this type of tubing.

Pneumatics industry

The pneumatics industry widely employs nylon tubing for piping pneumatic circuits. The tube’s close tolerance makes it ideal for use with push-in and compression-type fittings. The use of nylon tubing extends to vehicle air brake systems as well.

Brewery food, and beverage applications

This semi rigid nylon tubing is widely used in the Brewery dispensing industry for CO2 gas lines only.

Fuel ; Lubrication lines

Nylon has a good resistance to corrosion, which makes it ideal for use in both fuel and lubrication lines.

Technical Information – Imperial

| Part No. | OD | Tube ID | Working Pressure | Burst Pressure | Min. Bend Radius |

|---|---|---|---|---|---|

| ANI/062 | 1/8″ | .062″ | 725 P.S.I | 2900 P.S.I | 5/16″ |

| ANI/075 | 1/8″ | .075″ | 710 P.S.I | 2840 P.S.I | 5/16″ |

| ANI/096 | 5/32″ | .096″ | 520 P.S.I | 2080 P.S.I | 5/16″ |

| ANI/117 | 3/16″ | .117″ | 455 P.S.I | 1820 P.S.I | 3/18″ |

| ANI/137 | 3/16″ | .137″ | 305 P.S.I | 1220 P.S.I | 1/2″ |

| ANI/150 | 1/4″ | .150″ | 395 P.S.I | 1580 P.S.I | 3/18″ |

| ANI/170 | 1/4″ | .170″ | 375 P.S.I | 1500 P.S.I | 1/2″ |

| ANI/190 | 1/4″ | .190″ | 250 P.S.I | 1000 P.S.I | 1″ |

| ANI/212 | 5/16″ | .212″ | 375 P.S.I | 1500 P.S.I | 7/8″ |

| ANI/242 | 5/16″ | .242″ | 250 P.S.I | 1000 P.S.I | 1 1/4″ |

| ANI/250 | 3/8″ | .250″ | 400 P.S.I | 1600 P.S.I | 1″ |

| ANI/265 | 3/8″ | .265″ | 380 P.S.I | 1520 P.S.I | 1 1/4″ |

| ANI/295 | 3/8″ | .265″ | 355 P.S.I | 1420 P.S.I | 1 1/2″ |

| ANI/375 | 1/2″ | .375″ | 285 P.S.I | 1140 P.S.I | 1 1/2″ |

| ANI/500 | 5/8″ | .500″ | 220 P.S.I | 880 P.S.I | 2 1/2″ |

| ANI/594 | 3/4″ | .594″ | 225 P.S.I | 900 P.S.I | 4″ |

| ANI/813 | 1″ | .813″ | 205 P.S.I | 820 P.S.I | 7/8″ |

Metric Sizes

| Part No. | OD | ID | Working Pressure | Burst Pressure | Min. Bend Radius |

|---|---|---|---|---|---|

| ANM 4/25 | 4mm | 2.5mm | 415 P.S.I | 1600 P.S.I | 8mm |

| ANM 5/3 | 5mm | 3mm | 450 P.S.I | 1800 P.S.I | 10mm |

| ANM 5/33 | 5mm | 3.3mm | 425 P.S.I | 1700 P.S.I | 12mm |

| ANM 6/4 | 6mm OD | 4mm | 358 P.S.I | 1432 P.S.I | 13mm |

| ANM 8/55 | 8mm | 5.5mm | 332 P.S.I | 1328 P.S.I | 22mm |

| ANM 8/6 | 8mm | 6mm | 255 P.S.I | 1020 P.S.I | 32mm |

| ANM 10/7 | 10mm | 7mm | 317 P.S.I | 1268 P.S.I | 26mm |

| ANM 10/75 | 10mm | 7.5mm | 261 P.S.I | 1044 P.S.I | 43mm |

| ANM 10/8 | 10mm | 8mm | 200 P.S.I | 800 P.S.I | 50mm |

| ANM 12/85 | 12mm | 8.5mm | 277 P.S.I | 1108 P.S.I | 36mm |

| ANM 12/9 | 12mm | 9mm | 257 P.S.I | 1028 P.S.I | 45mm |

| ANM 12/95 | 12mm | 9.5mm | 234 P.S.I | 936 P.S.I | 53mm |

| ANM 12/10 | 12mm | 10mm | 164 P.S.I | 656 P.S.I | 60mm |

| ANM 16/12 | 16mm | 12mm | 193 P.S.I | 772 P.S.I | 85mm |

| ANM 22/17 | 22mm | 17mm | 230 P.S.I | 920 P.S.I | 140mm |

| ANM 25/20 | 25mm | 20mm | 200 P.S.I | 800 P.S.I | 180mm |

ID = Inside diameter

OD = Outer diameter

Technical details of our Nylon Tubing

The working pressures of these tubes and pipes are determined based on the short-term burst pressure calculated at 20°C, considering a 4:1 safety factor. Working and burst pressures of semi-rigid Nylon are approximately 60% higher than for flexible Nylon.

Recommended Operating Temperatures

It is recommended to use semi-rigid nylon for elevated temperatures up to 110°C, with intermittent use of temperatures up to 140°C. The maximum recommended continuous working temperature for nylon tubing is 70°C, with occasional limited periods of up to 120°C.

Any temperature increase above 20°C will affect the short-term burst pressure quoted for this product. The minimum operating temperature is -40°C.

To find out more about Nylon 12 please see this Wikipedia page.

Can’t find the right tube to meet your unique requirements?

If you require additional information about whether this tube is right for your application, our customer service team has decades of experience creating custom nylon tube solutions for various industries, including brewing. If you require a bespoke tube extrusion, don’t hesitate to contact us today.

Bespoke

Can’t find the right tube to meet your unique requirements?

We have decades of experience creating custom nylon tube solutions for various industries, including brewing. If you require a bespoke tube extrusion, don’t hesitate to contact us today.

Related Informational Articles about our Nylon Tubing

What are the Benefits of Nylon Tube?

Regarded highly for its exceptional stability, mechanical strengths and resistance to chemical corrosion, nylon is considered one of the most versatile engineering materials.

What are Nylon Tubes Used for?

Find out what type of uses this type of tubing is ideal for.

Made to Order Products

Is there a particular specification that you need to be met? We can create a bespoke hose that meets all your requirements and specifications. We work with several businesses regularly to offer the best solution for their needs. Read the examples below to see how we’ve helped several...

Nylon Tube VS PU Tube - How Do They Differ?

Find out how these types of tubing differ from each other.

19 Benefits Of Nylon Tube - A Comprehensive Guide

Nylon Tubing has a large number of advantages. These can include: Performance and Reliability.

1. High Tensile Strength Nylon tubing can withstand considerable force, making it highly reliable in high-pressure applications....