Polyurethane Tube

Polyurethane Tube, or PU Tube, is widely used in pneumatic control systems thanks to its resilience, tight bend radii, flexibility and suitability in low temperatures; our polyurethane tubing is a high-performance tube option that offers excellent capabilities and abrasion resistance.

or call us to discuss your requirements on:

01530 416177

Introducing our Premium Polyurethane Tubing, also known as PU Tube, the industry standard for reliability and durability. Ideal for a wide range of pneumatic applications, this tubing offers you a superior flexibility, kink-resistance, and a lightweight design to meet all your project needs.

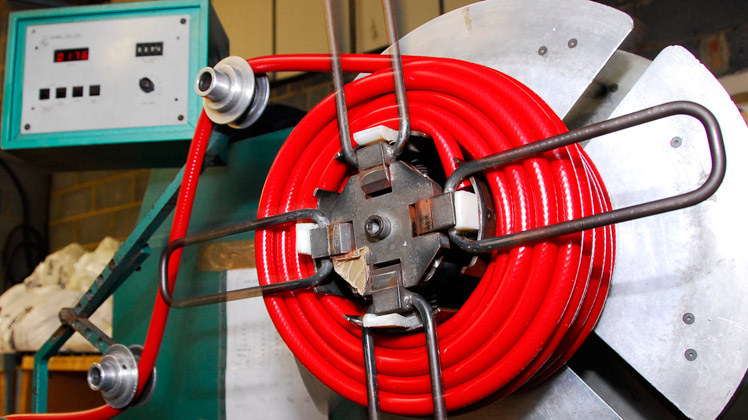

UK Polyurethane Tubing Manufacturer

As a UK polyurethane tubing manufacturer, we can extrude / manufacture and supply large quantities of this type of tubing to your bespoke criteria using our Midlands-based manufacturing facility.

We are regular suppliers of PU hose to many clients and have the capabilities and required documentation to allow for a one-off or a steady supply of this type of tubing.

So what makes Polyurethane tubing, or PU pipe, right for your requirements?

Urethane tubing has many properties, making this unreinforced polyurethane tube a versatile solution. For instance, it is resilient to abrasion, chemicals, gases, and most fuels, oils, greases, and other materials.

This type of tubing also possesses maximum kink resistance and minimum kink memory, making it an excellent choice for use in confined spaces. It is also silicone-free and REACH, RoHS and ISO compliant and is prevalent for pneumatic uses.

This tubing’s suitability in low temperatures and tight bend radii often makes it a superior choice to a nylon tube that does not possess the same qualities.

- Abrasion resilient

- Chemical resistant

- REACH, RoHS and BSI ISO 9001 compliant

- Silicone free

- Suitable in low temperatures

- Highly flexible with kink resistance

Some of Polyurethane Tubes’ main properties include:

Anti Bacterial Properties

Polyurethane does not support mould, mildew, fungus or other similar growth.

Abrasion, Impact & Shock Resistance

This property is ideal in helping to prevent our tubing from being damaged and causing the inner contents to leak and flow outside of the tubing due to exterior damage.

Material

High-grade polyurethane, known for its elasticity, tear-resistance, and long lifespan, makes this PU tube ideal for many application uses.

Polyurethane Tubing in Various Industries

Polyurethane tubing, known for its flexibility, durability, and resistance to abrasion, chemicals, and weathering, is widely used in various industries for a multitude of applications. Here are ten common uses of polyurethane tubing:

Pneumatic Control Systems

It is extensively used in pneumatic controls and machinery for conveying pressurized air due to its flexibility and high resistance to kinking and abrasion.

Fluid Handling

Polyurethane tubing is suitable for transferring fluids, including water, petroleum-based products, and some chemicals, because it is highly resistant to chemicals and abrasion.

Medical Devices

Because of its biocompatibility and flexibility, it’s used in medical applications like catheters and IV tubing.

Food and Beverage Industry

Approved grades of polyurethane tubing are used to transfer food products and beverages, as they do not affect the taste or odour of the contents.

Robotics and Automation

Its durability and flexibility make it ideal for wiring protection and fluid delivery in robotics and automated machinery.

Automotive Industry

Polyurethane tubing is used in automotive applications, including fuel lines and air intake systems, due to its resistance to oil, gasoline, and other chemicals.

Water Purification Systems

Due to its resistance to corrosion and scaling, it is used in water filtration and purification systems to transport water.

Pharmaceutical Manufacturing

In pharmaceutical manufacturing, it’s used for transferring sensitive fluids, benefiting from its chemical resistance and non-toxic properties.

Hydraulic Hoses and Fittings

Polyurethane tubing can be found in low-pressure hydraulic systems and fittings, offering a lightweight and flexible hose option.

Oil and Gas Industry

Because of their resistance to petroleum products and harsh environmental conditions, they are used for various applications in the oil and gas industry, including the extraction and refining process.

Polyurethane tubing’s combination of flexibility, durability, and resistance to various chemicals and environmental conditions makes it a versatile choice across a broad spectrum of applications, from industrial and automotive to medical and food processing.

Forms a Tight Seal

Due to polyurethane having tear and abrasion-resistant properties, it forms a tight seal locking out unwanted air ingress and preventing puncture – meaning the contents inside are safe from external factors.

Temperature Resistant Properties

PU tubing has excellent temperature resistance, and it can stand up to both intense heat and extremely cold environments.

Electrical Insulating Properties

Polyurethane has an excellent electrical insulating property.

Chemical & UV Resistance

This type of tubing is resistant to oil, fuel, and other commonly used chemicals, while it is also ideal for withstanding exposure to sunlight for long durations at the same time.

Flexibility

Our polyurethane tubing performs well for flexible applications with a tight bend radius. This unique tubing feature assists with maximum kink resistance and minimum kink memory, making it an excellent choice for use in confined spaces. This kink resistance helps prevent damage to the tubing, allowing easy movement to the tube installation.

High Load Bearing Capacity

Polyurethane exhibits a high compression load capacity compared to other materials like rubber. Under a heavy load, the material may experience temporary deformation; however, it will regain its original shape once the burden is removed.

Resistance to Gases, Fuels, Oils, and Water

Polyurethane will remain stable in or carrying: Gases, Fuels, Oils, and Water.

Creates Less Noise

Compared to other materials, such as metals or plastics, this tubing provides less noise when moving.

REACH, RoHS and ISO Compliant

Our Polyurethane tubing is REACH, RoHS and ISO compliant, which addresses the production and use of chemical substances and their impacts on health and the environment.

High Cut & Tear Resistance

This PU Tubing possesses high tear resistance along with high tensile properties.

Colour Coding Parts

We can pigment this type of tubing, providing a wide selection of colour options. This pigmentation is especially advantageous when you need to colour-code your tubing.

Versatilite

This type of tubing is suitable for various industrial, automotive, and medical applications.

Large Temprature Ranges and Pressures

This tubing operates efficiently from -20°C to 70°C and handles a wide range of pressures and vacuums, making it suitable for both high and low temperature and pressure applications.

Lengths & Colours

Our polyurethane (PU) tube is available in various sizes, ranging from 2.5mm inside diameter to 9mm inside diameter. All sizes are available in natural (opaque off white), tinges of brown, red, black, and blue.

The polyurethane tube has a standard coil length of 30 metres but is available in alternative sizes. Don’t hesitate to get in touch with our sales office for more information if you have any queries.

PU Tubing Uses

This unreinforced polyurethane tube is ideal for a large number of application uses. Some of these consist of the following:

- Low-pressure pneumatic application

- Hydraulic Control Systems

- Automotive applications

- Pneumatic control systems

- Transfer of Petroleum

- Fuel lines

- Grease and other forms of lubrication Lines

- Liquid lines

- Oxygen lines

- Gas lines

- Agriculture tubing

- Insulating sleeving

- Machinery tubing

- Air feeds

- Robotics

- Automotive lines

- Fluid Transfer

- Medical Equipment

- Along with many similar application uses

PU Tube Sizes

| Part No. | OD | ID | Working Pressure | Burst Pressure | Min. Bend Radius |

|---|---|---|---|---|---|

| APU 4/25 | 4mm | 2.5mm | 185 P.S.I | 470 P.S.I | 6mm |

| APU 5/3 | 5mm | 3mm | 160 P.S.I | 640 P.S.I | 8mm |

| APU 6/4 | 6mm | 4mm | 150 P.S.I | 600 P.S.I | 11mm |

| APU 8/55 | 8mm | 5.5mm | 135 P.S.I | 540 P.S.I | 19mm |

| APU 8/6 | 8mm | 6mm | 120 P.S.I | 480 P.S.I | 23mm |

| APU 10/75 | 10mm | 7.5mm | 110 P.S.I | 440 P.S.I | 25mm |

| APU 12/9 | 12mm | 9mm | 100 P.S.I | 400 P.S.I | 40mm |

ID = Inside diameter

OD = Outer diameter

Technical Details

The working pressures of this polyurethane tube are based on the short-term burst pressure at a temperature of 20°C using a 4:1 safety factor.

The maximum recommended continuous working temperature is 55°C with occasional short-term use at 85°C. Minimum temperature use is occasional use at -55°C.

The standard coil lengths are 30 metres; however, we provide customised solutions to our sales team if you are looking for alternative coil lengths. We will be happy to talk about your options. All tube sizes are also available in various colours and tints.

You can find out more about Polyurethane at this Wikipedia page

Bespoke

Can’t find the right tube to meet your unique requirements?

We have decades of experience creating custom tube solutions for various industries, from the pharmaceutical to the aeronautics sector.

Related Informational Articles about our Polyurethane Tubing

What is Polyurethane and why are our Polyurethane Tubes suitable in Pneumatic Control Systems

Polyurethane is a very flexible elastomer - a synthetic polymer with elastic properties. The main advantage of Polyurethane is that it has: Anti Bacterial Properties - Polyurethane does...

Made to Order Products

Is there a specific specification that you need to be met? We can create a bespoke hose that meets all your requirements and specifications. We work with several businesses regularly to offer the best solution for their needs. Read the examples below to see how we’ve helped several...

Nylon Tube VS PU Tube - How Do They Differ?

Find out how these types of tubing differ from each other.